THE TEST EQUIPMENT PARK EXPANDING

Within the framework of RSE NNC RK reactors conversion, Material Testing Department conducts incoming inspection of the water-cooled technological channels with low-enriched uranium fuel (WCTC-LEU) of the IVG.1M reactor and develops the IGR core immobilization technology removed from the reactor in 1966. New equipment is procured to solve these tasks. To date, electrodischarge machine (EDM), jaw crusher in a set with disc mill, auto mixer in a set with mold and universal hydraulic compression testing machine have been delivered.

Procurement of ARTA 123 PRO EDM (Fig.1) enables cutting fuel rods for sampling to conduct research. In comparison with operation of a machine of 1965 year of manufacture, which failed due to huge scope of work, the new one has the following advantages:

– no heating and deformation when sample cutting;

– a possibility of making small samples;

– minimum contact of personnel when working with active materials.

ARTA 123 PRO Machine will also be used in post-test analysis of irradiated fuel rods after life-cycle tests of 2 WCTCs-LEU in the IVG.1M reactor.

The main part of new equipment is designed for equipping of an individual laboratory for research work in support of stages of the IGR irradiated fuel immobilization technology. Currently, a laboratory room was prepared, as well as installation, connection and testing of new equipment are underway.

Chosen Tinius Olsen model of the testing machine (Fig.2) is used to determine mechanical properties of concrete block samples, which are models of a matrix for the IGR irradiated fuel. The machine provides maximum load of 600 kN, and hardware and software package allows remotely setting test conditions for tension, compression and bending of concrete block samples that is also important when working with irradiated samples.

The ELE Concrete Mixer Truck (Fig.3) will be used at one of the sages of pilot sample preparation of uranium-graphite fuel matrix.

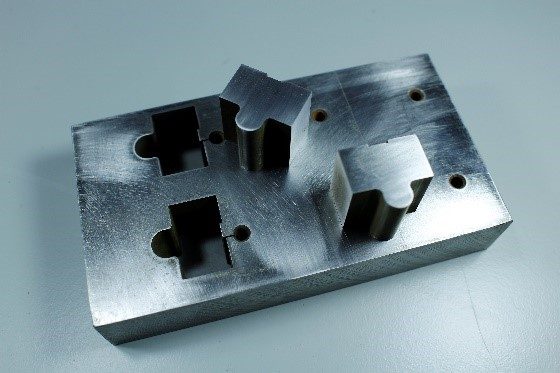

Combining of the PULVERISETTE 1 Jaw Crusher and PULVERISETTE 13 Disk Mill (Fig. 4) enables automatically milling material with a size of primary particles to 95 mm until final milling degree – 100 µm. After laboratory tests, combined unit will be used for technological purposes of IGR irradiated fuel immobilization.