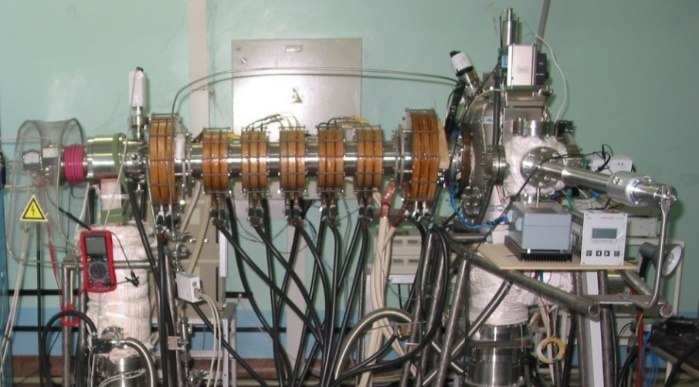

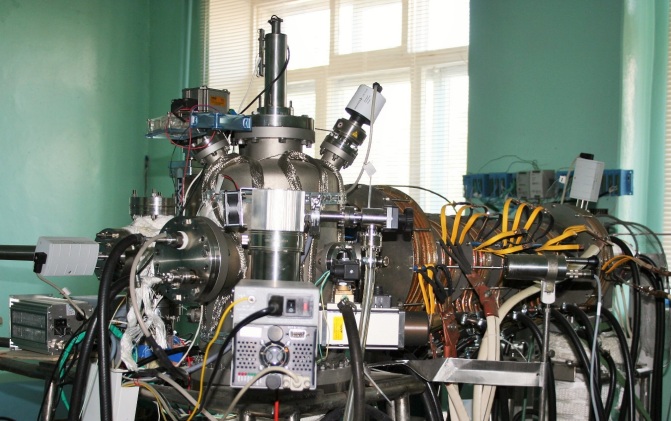

SIMULATION TEST-BENCH WITH PLASMA-BEAM INSTALLATION

The simulation test-bench with a plasma-beam installation is intended for testing structural materials of thermonuclear technology under conditions of plasma exposure and high thermal load. The diagnostic equipment of the test-bench allows studying the plasma-surface interaction and plasma physics.

Technical specification:

Electron source power …………………………………………….. 0 – 30 kW

Electronic temperature …………………………………………… 0 – 15 eV

Electron energy ……………………………………………………….. 0 – 20 keV

Electron beam diameter …………………………………………. 3 – 30 mm

Maximum gas pressure……………………………………………. <10-3 torr

Plasma ion energy …………………………………………………… 0 – 2 keV

Ion flux density ………………………………………………………… 1022 m-2·s-1

Maximum plasma concentration,

H2, D2 m-3 …………………………………………………………………. ~1·1018

He, N2, Ar, O2 m-3 ……………………………………………………… ~1·1018

The imitation test-bench has the following distinctive functionalities:

– electron beam scanning system, which allows to distribute the heat flux of electrons over the area of the cooled collector of the target assembly;

– several target vacuum devices with the ability to cool and control the temperature of the sample from the irradiated and back sides of the surface;

– system for programmed heating of the test materials for experimental work on thermal desorption in situ analysis.

The imitation test-bench with plasma-beam installation is capable to use hydrogen, deuterium, helium, argon, nitrogen, oxygen, air and a mixture of gases as working gases.

Main research area:

– study changing the structure and properties of structural materials of thermonuclear facilities under plasma irradiation and thermal exposure;

– modification of the material surface layer in order to improve performance;

– testing of diagnostic equipment for thermonuclear facilities under plasma exposure and heat load in various gaseous mediums;

– investigation of the interaction between low-temperature plasma and materials of the TNR divertor cladding and the first wall of the KTM Tokamak and TNR;

– obtaining protective coatings on the surface of TNR structural materials;

– improvement of methods and tools for diagnostics of low-temperature plasma.

- Conducting an experiment on plasma irradiation of a structural material

- Plasma-beam discharge