NUCLEAR INDUSTRY DEVELOPMENT IN THE REPUBLIC OF KAZAKHSTAN

Institute of Atomic Energy performs activity to substantiate the establishment and development of national nuclear industry. Within this area, following works are carried out:

- Feasibility studies to prove NPP construction in Kazakhstan also under the remit of the International Project on Innovative Nuclear Reactors and Fuel Cycles (INPRO);

- Development of legal and technical documents to ensure the formation of a comprehensive and self-sufficient regulatory and legal framework for the nuclear industry and nuclear power in Kazakhstan;

- Feasibility studies for further BN-350 spent nuclear fuel (SNF) management;

- Development of design for facilities and experimental devices under studies in support of safety of nuclear power plants.

EXPERIMENTAL STUDIES FOR NUCLEAR INDUSTRY SAFETY

COTELS Project

Severe accident research facilities were used for:

– experiments to produce reactor core melt (corium) and its moving towards the objects tested;

– experiments to study interaction between the melt and water ;

– experiments to study interaction between the melt and «dry» concrete trap;

– experiments to study interaction between the melt and reactor bottom material under supply of the water for cooling down outer surface of bottom mockup and simulation of residual heat in the melt;

– experiments to study interaction between the melt, water and concrete when the water coolant is supplied to the melt surface inside of the concrete trap and simulation of residual heat inside of the melt by means of electrical heaters.

- Solidified corium after interaction with coolant

- Concrete trap with inductive heater

- Cross section of the concrete trap with the solidified corium

- Simulation of residual heat release in the melt

Qualitative and quantitative database has been prepared which is essential to predict the progress of severe accident and to formulate the measures limiting and isolating its consequences.

EAGLE Project

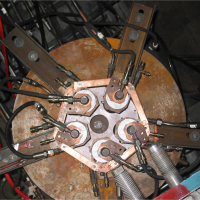

Currently, IGR reactor and EAGLE test bench is involved into experiments to substantiate the conception of controlled moving of fuel melt in fast reactors to prevent recriticality at severe accidents with core melting.

Out-of-pile studies for fast reactor safety include:

- experiments on producing melt with UO2 and corium simulator (Al2O3);

- experiments on moving UO2 corium through the discharge duct;

- experiments with aluminum oxide on moving corium simulator through the discharge duct filled with sodium;

- experiments on melt interaction with sodium coolant, including:

– melt fragmentation;

– melt cooling down in sodium pool.

- Top view on graphite crucible with rings of aluminum oxide

- Sodium flow setting device

- Cassette with UO2 pellets

- Cross section of upper melt trap after experiment with UO2

- Microstructure studies of solidified melt

In-pile experiments are implemented at IGR reactor using special experimental devices and methods.

- Mounting of model FA

- Test section before experiment

- Part of inner pipe and FA after experiment

- Melt trap after experiment

- Longitudinal section of the trap after experiment with sodium

INVECOR Project

The purpose of the INVECOR Project (IN-VEssel COrium Retention) is to improve the feasibility for the safe retention of melt in a light-water reactor vessel under severe accident conditions by means of experimental modeling of thermal and physicochemical processes during retention of a pool of molten prototype corium on the bottom of a water-cooled reactor vessel.

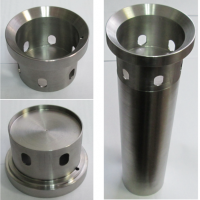

For the experiments, the Lava-B faciliuty was used, equipped with an induction furnace for producing a melt of 60 kg of prototype corium and a device for receiving a drained melt (MR) containing a water-cooled model of the bottom of the reactor power vessel, a device for simulating residual heat release with a power of up to 90 kW and a set of sensors temperature, pressure and deformation.

The main results of the Project: new experimental data on the final structure of the corium pool with natural convection when simulating residual heat release in fuel and ablation of the vessel bottom model with different melt compositions and thermal loads on the wall in a 2-D configuration with a real curvature of the reactor vessel bottom.

- Reactor pressure vessel bottom model prepared for the experiment

- Solidified melt in the bottom model after removal of the bulk fraction

CORMIT Project

The overall goal of the CORMIT (Corium and Refractory Materials Interaction Test) Project is to prepare for and carry out experimental researches on corium interaction with refractory materials which could be used as potential protective material for under-reactor melt trap. These researches enable to choose appropriate refractory coating material for under-reactor traps normally intended for enhancing safety of Japanese NPPs in case of severe accident with reactor core melting.

- A concrete melt trap with refractory blocks in the melt receiver of the LAVA-B facility

- Melt trap with blocks of refractory materials: before experiment

- Melt trap with blocks of refractory materials: after experiment

Fukushima Debris Project

The purpose of the Project: to produce solidified melt of fuel and structural materials of reactor core and further study of their properties. The data on the structure and physical and mechanical properties of resulted corium prototype are necessary for development of a debris removal procedure from damaged Fukushima reactors and selection of appropriate tools.

- Melt trap with investigated materials

- Solidified melt ingot in the trap after the experiment

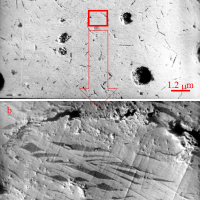

- Cross-section of an interaction area between the stainless steel and corium

SAIGA Project

In June 2019, a seven-year contract was signed between the National Nuclear Center of the Republic of Kazakhstan and the French Alternative Energies and Atomic Energy Commission (CEA) for the preparation and implementation of the SAIGA Project (Severe Accident In-pile tests for Generation IV reactors and ASTRID project) on the basis of the IGR reactor, aimed at studying the development of a severe accident in the core of the promising ASTRID reactor of French design.

Within the framework of this Project, studies of FA degradation of a sodium-cooled fast reactor equipped with a device for removing molten fuel from the core will be carried out. This test should be as representative as possible of the phenomena occurring during the sequence of events accompanying the development of a severe unprotected loss of coolant flow (ULOF) accident.

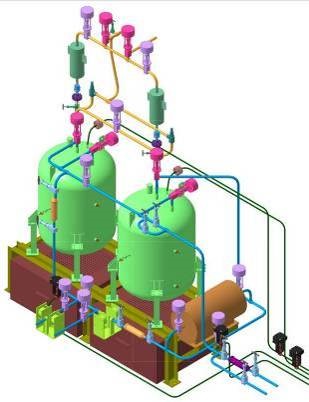

For the experiment, a sodium loop will be created, which will provide sodium flow inside the model FA, close to the nominal one in the ASTRID reactor. During modeling an emergency decrease in sodium flow, the IGR reactor will maintain a constant energy release in the fuel of a FA, as a result of which the FA will be destroyed with melting of the cladding and fuel of the fuel elements. The main purpose of research is the process and parameters of the propagation of this molten material in the FA.

- Diagram of an in-pile device with a model ASTRID FA

- Computational modeling of in-pile test modes

- Diagram of the sodium loop providing coolant (sodium) circulation through the in-pile device

BREST Project

On May 27, 2016, a meeting of the ME RK delegation was held in Moscow headed by Erlan G. Batyrbekov, Professor, Doctor of Physical and Mathematical Sciences, Director General of the RSE NNC RK, with management and leading specialists of the N.A. Dollezhal NIKIET, JSC (headed by Yuri G. Dragunov, Director and Designer General, RAS member-corr., Professor, distinguished designer of RF, D.Eng.Sc.), where it was discussed the issues of advanced scientific and technical cooperation when substantiating thermo-technical reliability of fuel elements and FAs of reactors like BREST and BN-1200, the main designer of which is NIKIET JSC.

Thus, close cooperation between RSE NNC RK and NIKIET JSC starts on preparation and implementation of research to study behavior of fuel elements with mixed nitride uranium-plutonium fuel of BREST-OD-300 under fast processes with increasing of energy release.

The main purpose of the tests is to determine threshold values of thermal loads leading to damage of claddings and fuel of the fuel elements.

During the work, calculation justification of an ampoule device structure and test modes of mock-ups of the BREST-OD-300 fuel elements at the IGR reactor were conducted, ampoule devices charged fuel element mock-ups were delivered to the CRR IGR, inter-channels tests were implemented and irradiated ampoule devices with fuel element mock-ups were shipped to the State Scientific Center – Atomic Reactor Research Institute (SSC ARRI), RF, for post-irradiation material research.

In 2021-2022:

– 9 experiments at the IGR reactor have been implemented with 5 ampoule irradiation devices, each of them contained 3 fuel elements with SNUP-fuel of the BREST-OD-300;

– Experimental data were obtained for defining the values of destructive energy release and operating temperature limit for fuel element cladding;

– Import and export of irradiation devices to Russia have been conducted.

- Loading of the experimental ampoule device into CEC of the IGR reactor

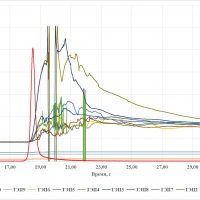

- Results of the in-pile experiment (“flush” mode)

- Loading of irradiated ampoule device into transport shielding container TUK-19 for transportation to SSC ARRI

EXPERIMENTAL STUDIES OF NUCLEAR/THERMONUCLEAR STRUCTURAL MATERIALS

Within scientific, technical and innovative activity of the IAE, experimental material testing studies of nuclear/thermonuclear structural materials are carried out. The main objectives of these studies are the selection of existing, the creation and testing of new, with increased technological requirements, structural materials, the study of the properties of fuel and structural materials in unique operating conditions in nuclear and thermonuclear facilities

- High-temperature material testing bench VCG-135

- Commercial X-ray diffractometer Empyrean (PANalytical)

- Raster electron microscope VEGA-3 equipped with adapter for Inca X-ACT energy-dispersive micro analysis

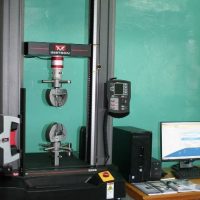

- Universal test machine Instron 5966 equipped with video extensometer AVE2

- The device for thermal gravimetric analysis and differential scanning calorimetry ТiGrА

- The section of optical metallography

- Microhardness tester Qness Q10А+

- The section of metallographic preparation equipment

To implement these objectives in the IAE there is unique experimental equipment and material research laboratories (material testing complex) located at the Complex of Research Reactors Baikal-1.

The main tasks cover the following lines:

- study of the structure and composition of the power reactor core materials after electro-thermal or reactor melting;

- studying the condition of core melt interaction products of power reactors with coolant, reactor pressure vessel material and concrete;

- studying the physicochemical interaction of core components at their heating up to the melting point;

- hydrogen penetration of structural fusion materials;

- identifying the main parameters of hydrogen isotope interaction with advanced fusion reactor materials;

- studying the influence of gaseous medium and irradiation on the diffusive, sorption and physical and mechanical properties of structural materials;

- analysis of gas medium samples generated during experimental work;

- study of the changes of structural-phase composition, corrosion resistance and physical and mechanical properties of structural materials after radiation, thermal and mechanical-thermal impact;

- certification of IAE’s reactor complexes;

- determination of HEU and LEU fuel properties of enterprise research reactors;

- conduction of thermal gravimetric analysis and differential scanning calorimetry of constructional material in the different environment under the temperatures up to 1600 °С;

- study of spectral – luminescent characteristics of nuclear-excited plasma, formed with nuclear reaction products;

- creation of new materials of hydrogen energy.

The IAE has well-outfitted material testing complex able to solve above research tasks.